The Ultimate Guide to Wire Ropes Types Uses and Benefits

Wire ropes are vital in many industries, from construction to maritime operations. Understanding the various types, uses, and benefits of wire ropes can greatly impact your operations. In this ultimate guide, we’ll answer your key questions about wire ropes to help you make informed decisions.

What Are Wire Ropes, and Why Are They Important?

Wire ropes are made by twisting multiple strands of metal wires together, creating a strong, flexible, and durable rope. This construction makes them ideal for tasks requiring significant strength and flexibility. Their versatility and strength have made them indispensable in various industries, including construction, mining, shipping, and manufacturing.

What Is the Structure of Wire Ropes?

Wire ropes consist of several components:

- Wires: These are the individual metal threads that form the strands of the rope.

- Strands: Groups of wires twisted together to provide strength and flexibility.

- Core: The central part of the rope, which can be made of either fiber, steel, or an independent wire rope core (IWRC). The core supports the strands and helps maintain the rope's shape.

What Are the Different Types of Wire Ropes?

Wire ropes come in various types, each designed for specific applications. Here’s a closer look at the most common types:

Single Layer Ropes

Single layer ropes feature a single layer of strands around the core. They are typically used for general lifting and pulling tasks where extreme strength is not required. They offer a good balance between strength and flexibility, making them suitable for many standard applications.

Multi-Layer Ropes

Multi-layer ropes have several layers of strands, providing enhanced strength and durability. They are used in heavy-duty applications, such as cranes and large-scale lifting operations, where greater load-bearing capacity is needed. The additional layers offer increased resistance to wear and tear.

Braided Ropes

Braided ropes are constructed by interlacing multiple strands in a crisscross pattern. This design provides excellent flexibility and resistance to abrasion. They are ideal for applications requiring a high degree of maneuverability and durability.

Spiral Wound Ropes

Spiral wound ropes are made by winding wires in a spiral pattern around the core. This construction offers superior flexibility and strength, making them suitable for dynamic applications where the rope needs to bend around pulleys or sheaves.

Coated Wire Ropes

Coated wire ropes have a protective layer of materials such as plastic or zinc. This coating enhances the rope's resistance to corrosion and environmental damage, extending its lifespan and maintaining performance in harsh conditions.

What Are the Key Features of Wire Ropes?

Understanding the key features of wire ropes can help you select the right one for your needs:

Strength and Load-Bearing Capacity

Wire ropes are designed to handle significant loads, and their strength depends on factors such as the type of wire, number of strands, and rope diameter. Their high strength-to-weight ratio makes them ideal for lifting and pulling heavy objects.

Flexibility and Bend Radius

Flexibility is crucial for applications that require the rope to bend around pulleys or sheaves. Wire ropes with a smaller bend radius offer greater flexibility, allowing for smoother operation in complex setups.

Durability and Wear Resistance

Wire ropes are engineered to withstand abrasion, corrosion, and other forms of wear. Their durability ensures long-term performance, reducing the need for frequent replacements and maintenance.

Corrosion Resistance

Coatings such as zinc or plastic protect the rope from environmental factors like moisture and chemicals. This protection helps prevent corrosion and extends the rope's lifespan, especially in outdoor or marine environments.

In What Industries Are Wire Ropes Used?

Wire ropes play a critical role in various industries, each with unique requirements:

Construction

In construction, wire ropes are essential for cranes, hoists, and elevators. They help lift and move heavy materials, making them indispensable for building projects and infrastructure development.

Mining

In mining, wire ropes are used in hoists and conveyors to lift and transport mined materials. Their strength and reliability are crucial for safe and efficient mining operations.

Shipping and Maritime

In the shipping and maritime industries, wire ropes are used for anchoring ships, securing cargo, and handling various marine operations. Their durability ensures safety and stability in challenging environments.

Manufacturing

Wire ropes are used in manufacturing processes to lift and move materials. They support machinery and equipment, contributing to efficient production and operations.

Entertainment and Rigging

In the entertainment industry, wire ropes are used for stage rigging, supporting and moving equipment and scenery. They are also employed in aerial performances, providing safety and support for performers.

What Are the Benefits of Using Wire Ropes?

Wire ropes offer numerous advantages, making them a preferred choice in various applications:

High Strength-to-Weight Ratio

Wire ropes are known for their exceptional strength relative to their weight. This high strength-to-weight ratio allows for efficient handling of heavy loads without adding unnecessary weight.

Flexibility and Versatility

The flexibility of wire ropes allows them to adapt to different configurations and applications. This versatility makes them suitable for a wide range of tasks, from lifting to securing.

Long Lifespan

With proper maintenance, wire ropes can last for many years. Their durability and resistance to wear and corrosion provide excellent value for investment.

Safety and Reliability

The robustness of wire ropes ensures safety in demanding applications. Their reliability reduces the risk of failure and accidents, making them a trustworthy choice for critical tasks.

How Should You Maintain and Care for Wire Ropes?

Proper maintenance is essential for maximizing the performance and longevity of wire ropes:

Regular Inspection

Regular inspection is crucial to identify signs of wear, corrosion, or damage. Check for frayed wires, broken strands, and kinks to ensure the rope remains in good condition.

Cleaning

Keep wire ropes clean to prevent corrosion and abrasion. Use appropriate cleaning agents and techniques based on the environment in which the ropes are used.

Lubrication

Applying lubrication reduces friction and wear, particularly in high-use applications. Regular lubrication helps maintain the rope's performance and extends its lifespan.

Proper Storage

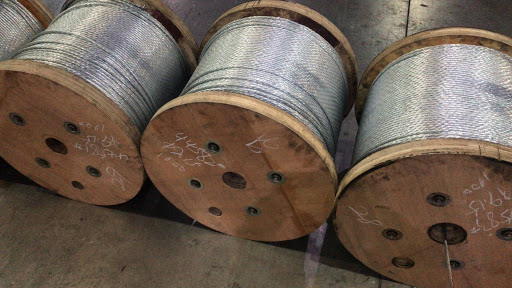

Store wire ropes in a dry, clean environment to prevent damage and deterioration. Proper storage helps preserve the rope's condition and ensures it remains ready for use.

How Do We Contribute to the Wire Rope Industry?

Since 1989, we have been involved in the wire rope manufacturing industry and stand as one of the leading Wire Rope Manufacturers in India.

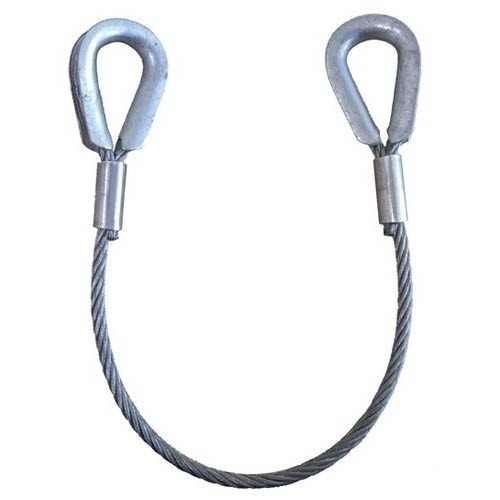

With over 30 years of experience and a commitment to quality, we produce a wide range of wire ropes to meet diverse industrial needs at reasonable prices. This includes galvanized wire ropes, ungalvanized wire ropes, elevator steel wire ropes, wire slings, and more. Although we are based in Chhattisgarh, we supply our products across the country. Thanks to India's excellent connectivity and robust transportation infrastructure, we efficiently deliver our products to regions including Nepal, Bhutan, Vietnam, and Dubai.

How Much Can We Manufacture and Supply?

To date, we have manufactured and supplied tons of wire ropes, supporting both small and large businesses across India and beyond. Our commitment to quality and innovation helps drive growth in various industries, contributing to the development of the country’s infrastructure.

Contact Us Today

For top-notch wire ropes tailored to your unique needs, don’t hesitate to get in touch with us! Visit our website at www.vikrantropes.com, call us at +91-9755556727, or drop us an email at parthosaha@vikrantropes.com. Our team is ready to provide expert solutions and support for all your wire rope requirements