How Wire Rope Slings Play an Important Role in Lifting or Rigging Applications

When it comes to lifting heavy loads, whether on a construction site, in a warehouse, or during a specialized rigging operation, the tools you choose can make all the difference. Among these tools, wire rope slings stand out as unsung heroes. You might not think much about them when you see them in action—they're often just hanging there, quietly doing their job while lifting tons of weight. But wire rope slings play an incredibly important role in ensuring safety, stability, and efficiency in lifting and rigging applications.

In this article, we’ll explore what wire rope slings are, why they’re so crucial in the lifting world, and some real-life scenarios where they truly shine.

Understanding Wire Rope Slings

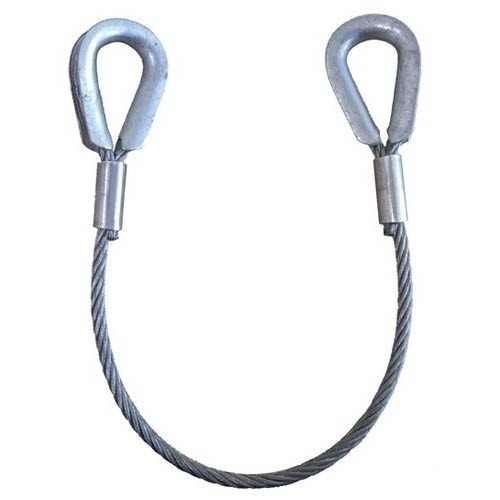

First things first: what exactly are wire rope slings? Simply put, wire rope slings are flexible assemblies of wire rope with various end fittings designed to facilitate the lifting and moving of heavy items. These slings are an essential component of rigging systems, which are commonly used in construction, manufacturing, and various transportation applications.

Types of Wire Rope Slings

Wire rope slings come in different types to accommodate diverse lifting requirements. Some of the most common ones include:

- Single Leg Slings: These consist of a single looped wire rope and are often used for hoisting lighter loads.

- Double Leg Slings: These are two-leg slings that provide more stability and have a greater load capacity, making them ideal for heavier items.

- Multi-Leg Slings: With three or more legs, these slings are designed to handle complex rigging needs and are excellent for distributing loads evenly.

- Braided Slings: Featuring multiple interwoven ropes, these slings offer enhanced strength and flexibility for intricate lifting tasks.

Understanding the specific requirements of your lifting task is crucial for selecting the right type of wire rope sling.

The Importance of Wire Rope Slings in Lifting Applications

1. Strength and Durability

Wire rope slings are incredibly strong and robust, capable of bearing heavy loads with ease. For instance, high-quality steel wire slings can withstand thousands of kilograms of weight, making them a preferred choice in industries requiring significant lifting capacities—construction, oil and gas, and shipping, to name a few.

2. Versatility

One of the most remarkable attributes of wire rope slings is their versatility. They can be employed in various applications, from lifting machinery and construction materials to moving heavy containers in warehouses. Plus, with the availability of different configurations and sizes, these slings can be adapted to specific tasks.

3. Safety Assurance

When it comes to lifting and rigging, safety is paramount. Wire rope slings are designed with various safety factors in mind. Most manufacturers, including Vikrant Ropes, ensure that the ropes undergo rigorous testing to meet safety standards. A well-maintained wire rope sling can significantly reduce the risk of failure during a lift, thereby protecting both personnel and equipment.

4. Cost-Effective Solutions

While wire rope slings may have a higher upfront cost compared to some synthetic alternatives, their longevity and durability can lead to lower overall costs in the long run. Heavy-duty wire rope slings can endure a multitude of uses before showing signs of wear and tear, making them a wise investment for businesses dealing with frequent lifting operations.

5. Ease of Use

Wire rope slings are also user-friendly. With their flexible nature, they can be easily hooked to cranes or lifting equipment and positioned without hassle. They can wrap around loads of various shapes and sizes, facilitating easy and effective lifting.

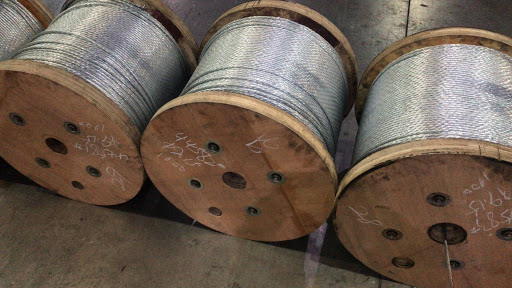

Recent Trends: Wire Rope Slings in Statistics

In recent years, the usage of wire rope slings has experienced a noticeable surge. According to industry reports, the demand for wire rope slings has risen by approximately 15-20% annually over the past five years. This increase can be attributed to the growing construction and manufacturing sectors, which necessitate reliable equipment for heavy lifting.

Industries around the world are increasingly opting for wire rope slings, acknowledging their advantages over other lifting systems. With an expanding market, wire rope slings are now considered one of the best options for lifting and rigging applications.

Comparing Wire Rope Slings to Other Options

While synthetic slings have their merits, wire rope slings provide unique benefits that make them the preferred choice in many scenarios:

- Durability: Synthetic slings may suffer from wear and tear in rough environments, while wire rope slings are resistant to cuts and abrasions.

- Weight Handling: Wire rope slings typically have a higher weight capacity, making them suitable for heavy lifting tasks where synthetic alternatives may fall short.

- Temperature Resistance: Wire rope slings can withstand extreme temperatures, making them suitable for challenging environments.

Other Applications of Wire Rope Slings

The applications of wire rope slings are practically endless. Here are some common areas where you'll find them shining:

- Construction: Lifting heavy materials like steel beams, precast structures, and concrete blocks.

- Mining: Used for transporting heavy machinery and raw materials.

- Maritime: Essential for lifting and securing loads on ships and in ports.

- Manufacturing: Used in assembly lines for lifting components and finished products.

- Logistics: Handy in warehousing for efficiently moving heavy items.

Features of Wire Rope Slings

Wire rope slings come equipped with various features designed to enhance their performance:

- Thimbles: These are protective devices that help maintain the shape of the sling eye, preventing wear at critical points.

- End Fittings: Depending on your application, slings can have hooks, eyes, or other attachments that make them easy to connect to loads.

- Multiple Configurations: Wire rope slings can be crafted in single, double, or multi-leg configurations, providing flexibility based on load dispersal needs.

How to Maintain Wire Rope Slings

Maintaining wire rope slings is essential to ensure safety and extend their service life. Here are some key maintenance tips:

- Regular Inspections: Conduct routine inspections for signs of wear, including kinks, frays, and rust.

- Proper Storage: Store slings in a cool, dry place and away from direct sunlight or chemicals that could lead to deterioration.

- Cleanliness: Keep the slings clean. Dirt and debris can lead to damage over time, so periodic cleaning is essential.

- Avoid Shock Loads: Shocking loads can put undue stress on slings. Always lift loads smoothly and steadily.

- Tagging and Documentation: Proper documentation of sling use, inspections, and maintenance can help determine when to retire a sling.

How to Choose the Right Wire Rope Slings

With different types of slings available, how do you choose the right one? Here are a few factors to consider:

- Load Type and Weight: Assess the load you’ll be lifting. Make sure the sling can handle the weight and shape.

- Environment: Consider the working conditions (outdoor, exposure to chemicals, marine environments) as some slings may perform better than others in specific conditions.

- Length and Configuration: Determine how long the sling needs to be and whether you’ll need a single leg or multi-leg option.

- Safety Factors: Always factor in the safety margin. It's better to err on the side of caution.

The Future of Wire Rope Slings

As industries continue to evolve, so too will the applications of wire rope slings. The future looks promising, with innovations in materials, safety features, and design all on the horizon. Manufacturers like Vikrant Ropes are continuously investing in research and development to stay at the forefront of this evolving field.

Conclusion

Wire rope slings are an indispensable part of lifting and rigging applications across many industries. Their strength, versatility, safety features, and cost-effectiveness make them a go-to choice for businesses looking to enhance their operational efficiency. Whether you’re lifting machinery on a construction site, transporting goods in a warehouse, or handling materials in manufacturing, wire rope slings undoubtedly play a vital role.

At Vikrant Ropes, we take pride in we are one of the reliable Wire Rope Slings Manufacturers in India and supply our high-quality wire ropes and slings all over the world that are designed with excellence and innovation. We encourage you to consider wire rope slings for your lifting applications and explore the diverse range of products we offer. Don’t hesitate to reach out to us for more information or specific inquiries!