Galvanized Wire Ropes vs Stainless Steel Wires Which is Better for Your Application

When it comes to lifting, rigging, and other demanding applications, choosing the right wire rope material is crucial for ensuring safety and durability. Two of the most popular materials for wire ropes are galvanized steel and stainless steel. Both options have their own advantages and limitations, making it important to understand their differences before making a decision.

In this article, we will delve into the features, benefits, and applications of galvanized wire ropes and stainless steel wires, ultimately guiding you toward choosing the most suitable option for your needs.

Understanding Galvanized Wire Ropes

What are Galvanized Wire Ropes?

Galvanized wire ropes are steel wires that have undergone a galvanization process, where a layer of zinc is applied to prevent rust and corrosion. This process enhances the longevity and durability of the wire ropes, making them suitable for a variety of environments and industries.

Manufacturing Process

The steel wires are first formed into strands, then coated in molten zinc before being twisted together to create strong, resilient wire ropes. This meticulous process ensures that galvanized wire ropes meet superior quality standards.

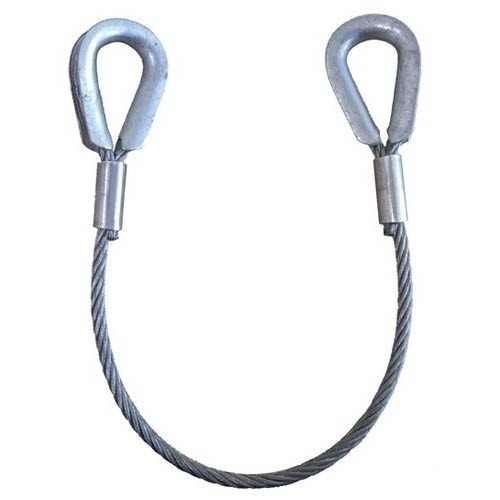

Applications of Galvanized Wire Ropes

Galvanized wire ropes are diverse in their applications and are commonly used across industries, including:

- Construction: Perfect for lifting materials and rigging, galvanized wire ropes provide strength and resilience on job sites.

- Marine settings: Due to their corrosion-resistant properties, they’re ideal for boat rigging and mooring purposes.

- Aerospace and Aviation: For safety harnesses and rigging, galvanized wire ropes deliver the necessary toughness.

- Agricultural Use: They are often used in fencing and support for crops.

According to industry statistics, the demand for galvanized wire ropes has increased by approximately 35% over the last five years, reflecting their growing importance, particularly in the construction sector.

Exploring Stainless Steel Wires

What are Stainless Steel Wires?

Stainless steel wires are made primarily from iron, chromium, and nickel, providing a strong resistance to corrosion and high temperatures. They are known for their aesthetic appeal, durability, and ability to withstand harsh environmental conditions.

Manufacturing Process

The production of stainless steel wires involves alloying different metals with iron and manufacturing them into wire forms. While this process often results in very resistant wires, it can also make them more expensive compared to their galvanized counterparts.

Applications of Stainless Steel Wires

Stainless steel wires are employed in numerous applications, including:

- Food Processing: Their resistance to corrosion makes them ideal for environments where hygiene is paramount.

- Medical Equipment: Stainless steel wires are essential for surgical instruments and implants.

- Architecture: They are often used in decorative features due to their aesthetic qualities.

While they are known for their strength and rust resistance, plasticity in applications requiring flexibility can be limited compared to galvanized wire ropes.

Galvanized Wire Ropes vs. Stainless Steel Wires: A Comparison

Corrosion Resistance

- Galvanized Wire Ropes: The zinc coating provides excellent protection against mild corrosive environments, making them suitable for general use.

- Stainless Steel Wires: These offer superior corrosion resistance, making them the preferable choice for highly corrosive environments such as marine and chemical applications.

Cost

- Galvanized Wire Ropes: Typically more affordable than stainless steel alternatives, they offer a cost-effective solution for many standard applications.

- Stainless Steel Wires: While they come with a higher upfront cost due to the raw materials, their longevity may justify the investment depending on the application.

Strength and Durability

- Galvanized Wire Ropes: Very strong and durable, they can withstand heavy weights, but they may be more susceptible to fatigue over time, especially in abrasive conditions.

- Stainless Steel Wires: They offer excellent tensile strength and are less prone to wear under harsh conditions.

Weight

- Galvanized Wire Ropes: Slightly heavier than stainless steel wires, which may be a factor when considering transport and installation.

- Stainless Steel Wires: Generally lighter, making them easier to handle for certain applications.

Overview of Galvanized Wire Ropes and Stainless Steel Wires

Now that we have an understanding of both galvanized wire ropes and stainless steel wires, let’s compare their features in a side-by-side format:

|

Feature |

Galvanized Wire Ropes |

Stainless Steel Wires |

|

Corrosion Resistance |

Good (zinc coating) |

Excellent (high chromium content) |

|

Cost |

More affordable |

More expensive |

|

Strength and Flexibility |

High strength and good flexibility |

High strength, but can be less flexible |

|

Environmental Resistance |

Suitable for moderate environments |

Ideal for aggressive environments |

|

Applications |

Construction, mining, agriculture, marine |

Decorative, architectural, high-temperature applications |

Which One Should You Choose?

Selecting the right wire rope depends heavily on the specific requirements of your application:

- If your needs involve cost efficiency, strength, and general environmental resistance, galvanized wire ropes are likely your best choice. Their affordability, combined with exceptional performance in moderately corrosive environments, makes them ideal for construction and general industrial purposes.

- On the other hand, if your application involves extreme conditions, such as exposure to saltwater or high-temperature environments, stainless steel wires may be your better option. Their higher resistance to corrosion and durability is unmatched, though this comes at a premium price.

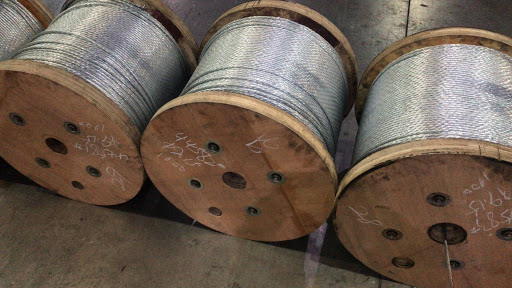

How Vikrant Ropes Stands Out

As one of the galvanized wire rope manufacturers in Chhattisgarh, India, we at Vikrant Ropes have produced high-quality galvanized wire ropes that can meet diverse industrial needs. Our commitment to excellence ensures that each product we deliver is crafted to the highest standards, providing safety and efficiency to our clients.

To date, we have supplied thousands of tons of galvanized wire ropes, assisting businesses from small startups to large enterprises in achieving their operational goals. By providing top-tier wire ropes, we contribute to the growth and development of various industries throughout the country.

Conclusion

In conclusion, the choice between galvanized wire ropes and stainless steel wires comes down to the specifics of your application, including environmental factors, budget constraints, and performance requirements. Both options have their unique advantages, and by evaluating your needs, you can make an informed decision.

At Vikrant Ropes, we are dedicated to supporting your enterprises with high-quality products that facilitate growth and innovation. If you're seeking reliable, durable galvanized wire ropes for your next project, contact us today. Let us help you elevate your business while contributing to the progress of the industrial landscape